Shaping the microbiological synthesis platform of the future together

The exponential increase in the volume of global data presents an enormous challenge. Traditional data storage solutions are reaching their limits, which is why alternative approaches are being explored. One promising possibility is the use of DNA as a data storage medium. However, current methods for microbiological synthesis of the data are still inefficient and resource intensive. To overcome these hurdles, the Fraunhofer-funded project "BIOSYNTH" is working on the development of a high-throughput microchip platform for the synthesis of DNA, RNA and peptides.

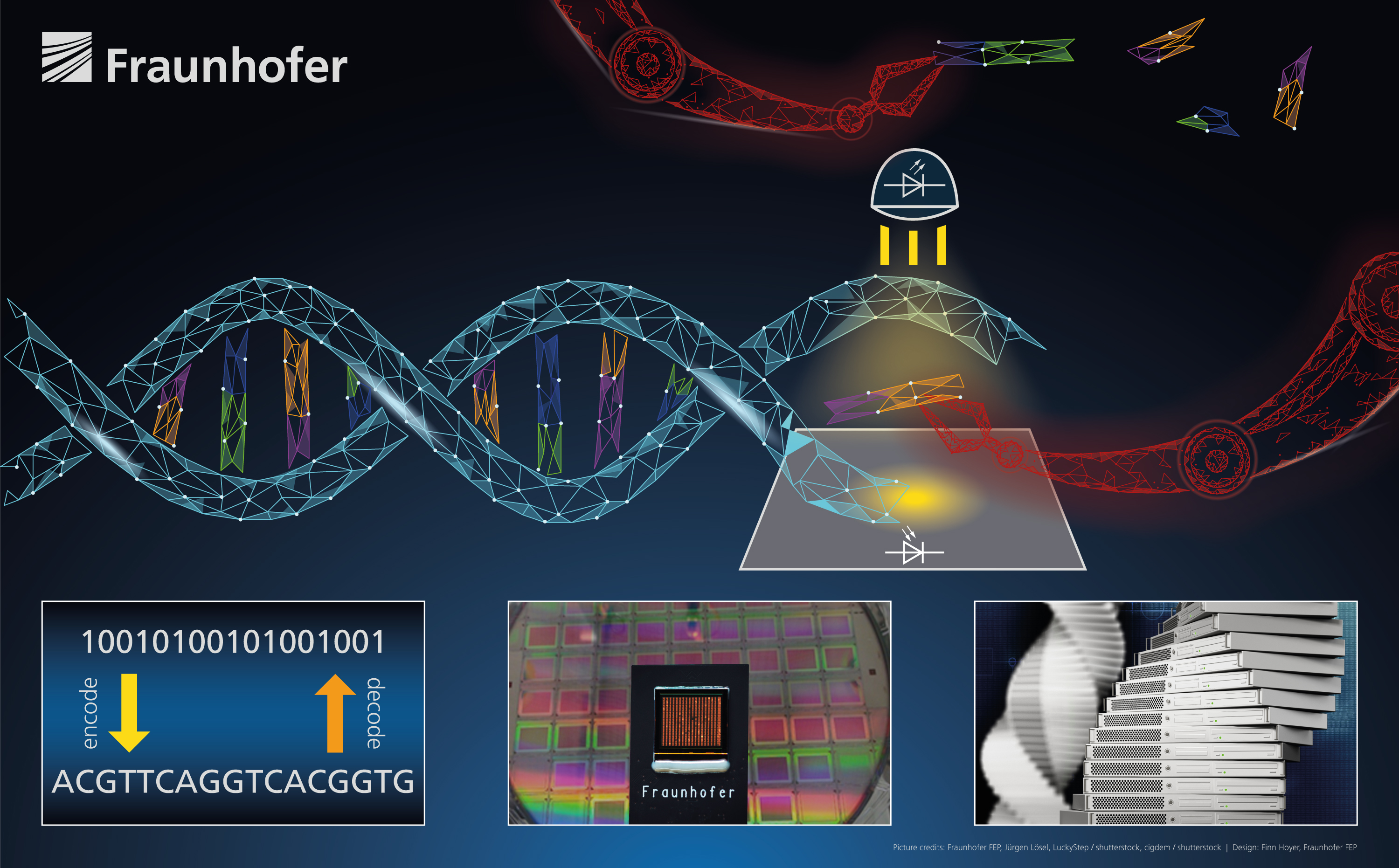

The global volume of data is growing daily to the size of several terabytes. Much of this data must be stored and archived over the long term, and current technical possibilities are foreseeably reaching their limits. DNA as a storage medium is a real alternative here, but the microbiological synthesis of the translated data is still not very efficient and is imprecise and resource-intensive. Parameters such as high information density and lifetime as well as low energy costs are highly relevant. DNA is not only a storage medium for genetic information, but can also be used to store data. When using DNA as a mass data storage medium, digital information, i. e. a conventional binary code, is first translated into a genetic code, i. e. DNA sequences. Subsequently, these sequences are synthesized and stored. The coding and also the decoding of the data takes place digitally.

However, machine processes are necessary for the synthesis and sequencing of DNA. The essential prerequisite for the development of a biological mass data storage device with high storage density and durability is a significant improvement in DNA synthesis, for which no high-throughput technology is yet available. Current synthesis approaches are very inefficient, especially in the production of long DNA segments, and generate inaccuracies that are time-consuming and expensive to correct. In addition, the equipment technology has so far been extremely space- and cost-intensive.

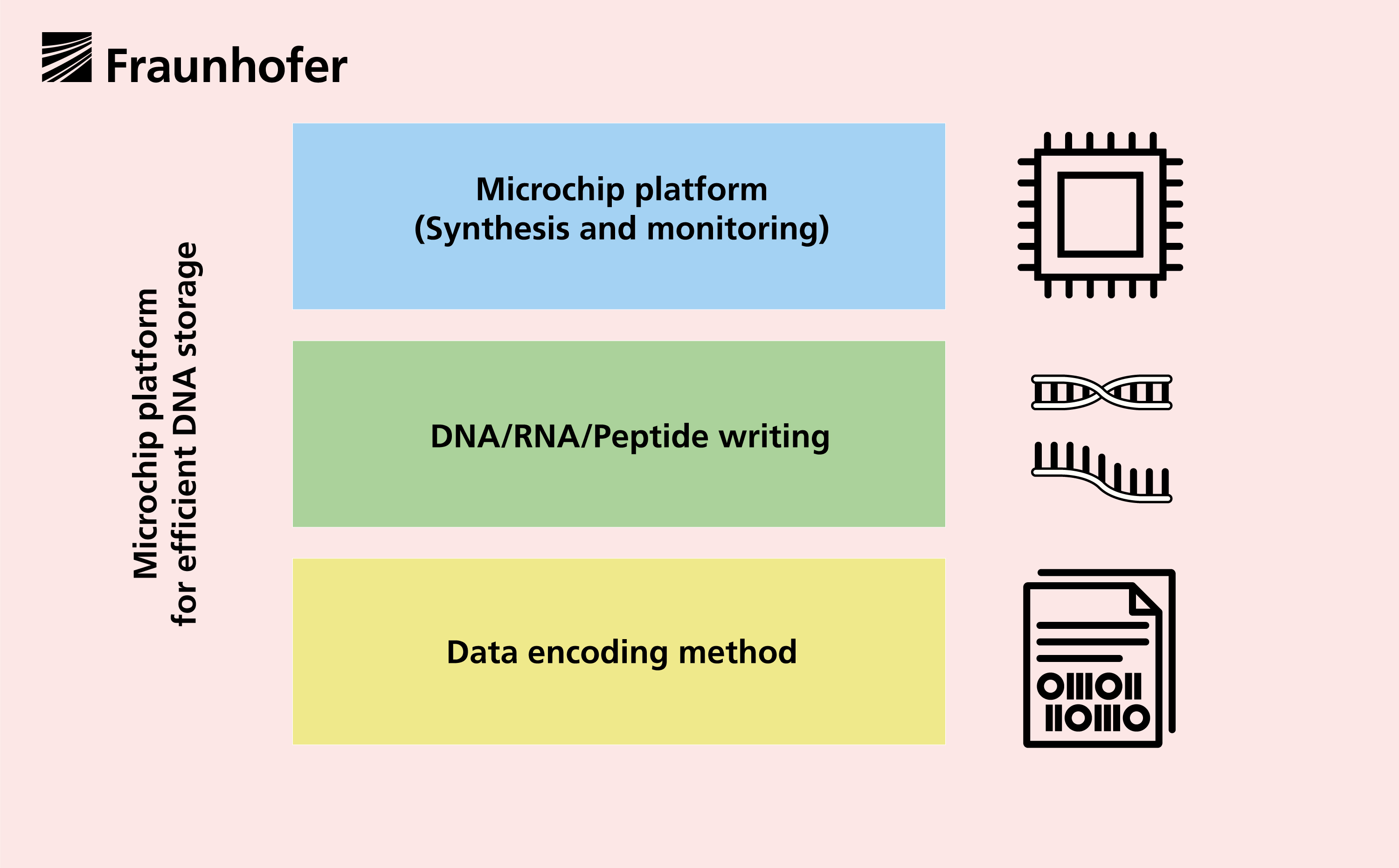

The research and development of a high-throughput microplatform for DNA, RNA or peptide synthesis, among other things for future mass data storage, is the goal of the Fraunhofer-funded project "BIOSYNTH". In order to be able to align the research work with the needs of future users at an early stage, the scientists of the participating Fraunhofer institutes FEP (coordination), IPMS, IZI-BB and ITEM want to exchange information with potential users in an interdisciplinary manner. In a workshop for potential users on December 5, 2023, they will present first insights into the results and technology demonstrators and at the same time seek a dialog with you.

Microbiological synthesis with high-throughput microplatform

The microchip platform to be developed for writing software-defined nucleotide sequences (e.g. DNA, RNA or peptides) is intended to enable the high-throughput, highly parallel production of mass data storage devices in the future by duplication in the mass production processes of the microelectronics industry. With the help of the platform, today's space-filling synthesis devices are to be replaced by portable, low-energy and low-cost systems through miniaturization, thus enabling commercial, biologically based data storage.

In addition, the platform can also be an important component for other applications such as eco- and food toxicology (including non-target screening), individualized therapies, bio-computing or in logistics.

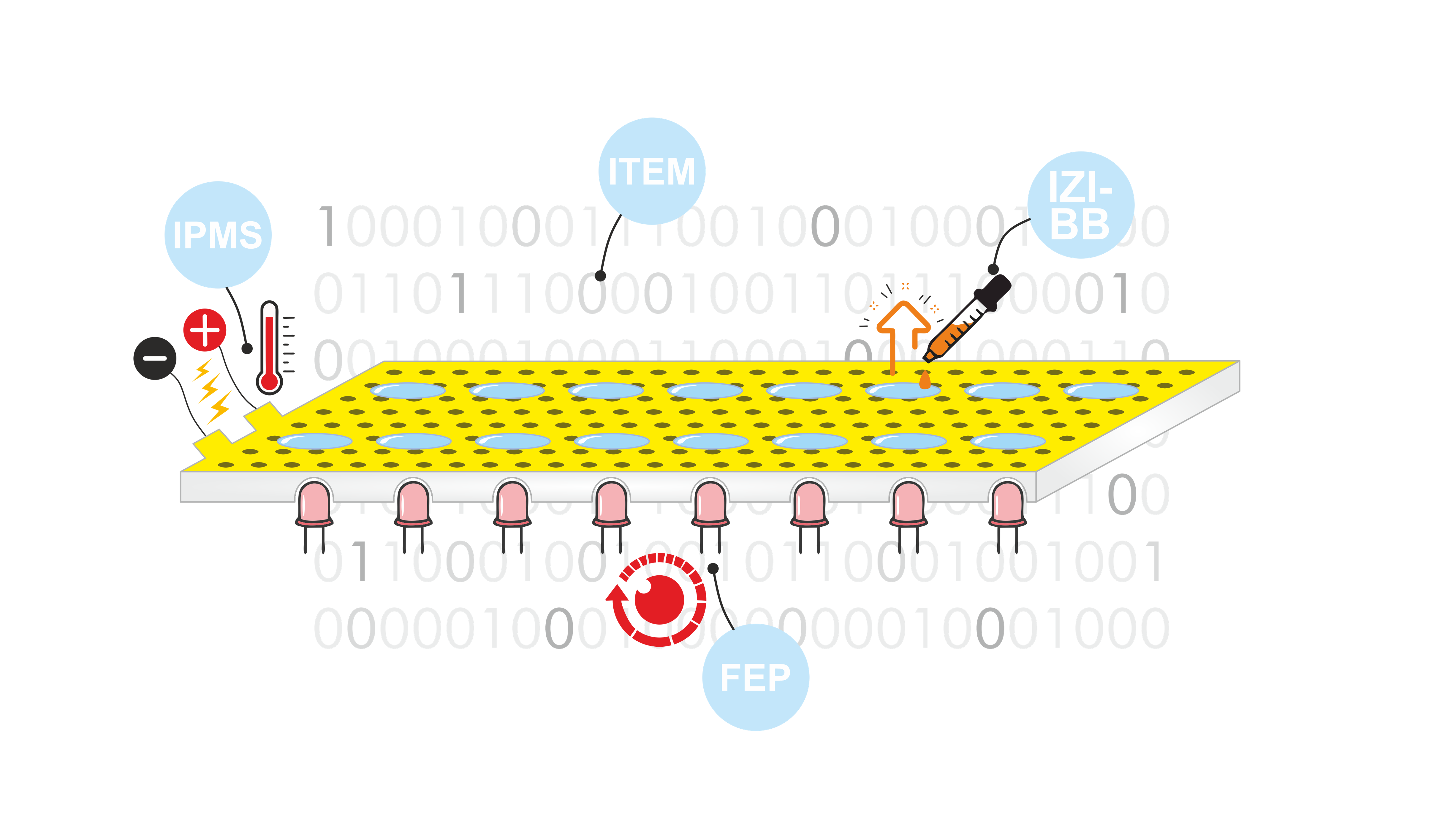

Since the start of the project in 2022, the researchers have already achieved initial results in the individual subprocesses. For the future microchip platform, Fraunhofer FEP is designing the integrated circuit of the CMOS backplane to control and readout the microheaters for biosynthesis and the control for the OLED and photodetector pixels in the active matrix array for photoactivation as well as process control.

Dr. Uwe Vogel, division manager for microdisplays and sensor technology at Fraunhofer FEP and coordinator of the project explains: "In addition to CMOS development, we are currently working on a specially adapted OLED frontplane and its technological co-integration with the heating system of Fraunhofer IPMS to support the synthesis. We are also investigating its influence on the downstream components and processes of the microchip platform. Promising initial trials have already been run here. The other institutes also achieved initial results, which we would like to present in a workshop at the end of the year."

User workshop for the custom-fit development of the microchip platform

In order to develop both the microchip platform and the microbiological synthesis processes specifically to meet future requirements, the research consortium will organize an end-user workshop in December 2023. The initial development results will be presented and discussed to a selected group of participants.

Dr. Vogel comments: "We would like to enter into discussions with potential users of such a microchip platform at an early stage. At the moment, there are only a few research activities in this field in Europe. However, the potential of this technology can be groundbreaking and bring enormous improvements for a wide range of application areas. That's why exchange and early coordination with other experts from other industries are important for us. Only in this way can we address the requirements of potential users that we may not even have envisaged until now."

Fraunhofer IPMS is developing the part of the microchip platform with the heating function to adjust the temperature for biological synthesis. This function is achieved by structures in surface micromechanics following the technology of Capacitive Micromachined Ultrasonic Transducers (CMUT). In addition, Fraunhofer IPMS is responsible for the realization of a MEMS technology that can integrate the OLED and photodetector pixels. In the workshop, Fraunhofer IPMS will present a first technology demonstrator of a controllable heater array demonstrating the structures in surface micromechanics with open membranes.

Fraunhofer IZI-BB contributes its expertise in cell-free bioproduction, microfabrication technologies, microfluidics and biochemical synthesis to the BIOSYNTH project and is responsible for the synthesis processes for DNA production. Fraunhofer IZI-BB scientists will demonstrate the synthesis of DNA on a Fraunhofer IPMS heater array at the user workshop.

To implement data storage on this new platform, the Bioinformatics group at Fraunhofer ITEM is developing special coding processes in biological components. In December 2023, the institute will already present the coding of DNA and the processes to date for this as an example. For this purpose, the topics of data conversion, error-correcting codes, and possible Big Data technologies for the project will also be highlighted. At the workshop, ITEM will show examples of the coding schemes specially tailored to the microchip platform as well as data compression with a focus on write speed.

To ensure scientific methodology, industrial compatibility and application relevance, the project and the Fraunhofer consortium have been supported since the beginning by an advisory board, which includes representatives of the University of Marburg, the Federal Archives and the companies X-FAB Semiconductor Foundries, Infineon Technologies and Hybrotec.

At the workshop, on December 5, 2023, researchers from all project partners as well as the BIOSYNTH project advisory board will be available for an inspiring open and interdisciplinary exchange on the platform technologies and future application fields of the high-throughput microplatform - also beyond data storage! Interested companies and partners are invited to register for the workshop in Dresden (pre-registration required). First technology demonstrators and research results will be presented in papers and poster sessions by the project partners.

About the project „BIOSYNTH“

BIOSYNTH - Modular high-throughput micro-platform for future synthetic biology mass data storage.

Funded by Fraunhofer-Gesellschaft e.V. within the internal „PREPARE“ program (40-03168).

Duration: 1. June 2022 – 31. May 2025

Project partners:

- Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP

- Fraunhofer Institute for Photonic Microsystems IPMS

- Fraunhofer Institute for Cell Therapy and Immunology, Branch Bioanalytics and Bioprocesses IZI-BB

- Fraunhofer Institute for Toxicology and Experimental Medicine ITEM

Advisory Board:

- Prof. Dr. Anke Becker, Philipps-Universität Marburg

- Christoph Kögler, Infineon Technologies, Dresden

- Volker Herbig, X-FAB Group, Erfurt

- Timo Dommermuth, Bundesarchiv Koblenz

- Jörg Schenk, Hybrotec GmbH, Potsdam

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam