Innovative surface-modified TiO2 coatings offer new hygiene solutions for interiors in health and care facilities

Every year, around four million people in Europe suffer healthcare-associated infections. Pathogens spread quickly via surfaces such as handrails, handles or touchscreens. To reduce the spread of pathogens, particularly in hospitals but also in public buildings, the EU-funded joint project SanFlex is researching a photocatalytic coating that is (additionally) grafted with super-acidic surface properties. This prevents the adhesion of pathogens and eliminates microorganisms as well. The aim of the project is to develop appropriate coating technologies for the cost-effective production of antipathogenic protective films for touchscreen applications. At the BAU 2025 trade fair in Munich, Germany, from January 13-17, 2025, the Fraunhofer FEP researchers will be presenting their initial results at the joint Fraunhofer stand no. 528 in Hall C2.

With the onset of the colder season, infectious diseases and flu epidemics are on the rise again. Surfaces such as handrails, handles and touchscreens and other high-traffic surfaces pose risks of transmission of pathogens. This is particularly severe in health care institutions where a large number of infected people aggregate. In Europe, around 4 million healthcare-associated infections are recorded every year, including 600,000 in Germany1,2. To reduce the spread of these germs, surfaces with antimicrobial properties can make a significant contribution to mitigate pathogen transmission.

Titanium oxide coatings, in particular crystalline titanium dioxide (TiO2), are known for their antimicrobial and self-cleaning properties. The Fraunhofer FEP is a well-known R&D institution that has developed and transferred coating systems and associated coating processes into industrial production for many years. In addition to coatings on rigid substrates such as glass, the institute's scientists also develop surface coatings and the functionalization thereof for flexible materials like polymer web and ultra-thin glass.

As part of the m.ERA.NET SanFlex research project, a Swedish-German consortium is researching new coating technologies to effectively reduce pathogens on surfaces. To realize this, the team is developing a new type of titanium oxide layers that are modified to create super-acidic surfaces.

Doubly effective antipathogenic coatings thanks to super-acidic surfaces

The super-acidic surface properties are generated by a photo-fixation process, while the photocatalytic properties of the titanium oxide layers are kept unaffected. This super-acidic coating has oleophobic and catalytic properties that prevent grease and pathogens from attaching to the surface. The coating acts as an antipathogenic protection that combines two properties in one product: the attachment of pathogens is initially prevented and at the same time microorganisms on the surface are eliminated.

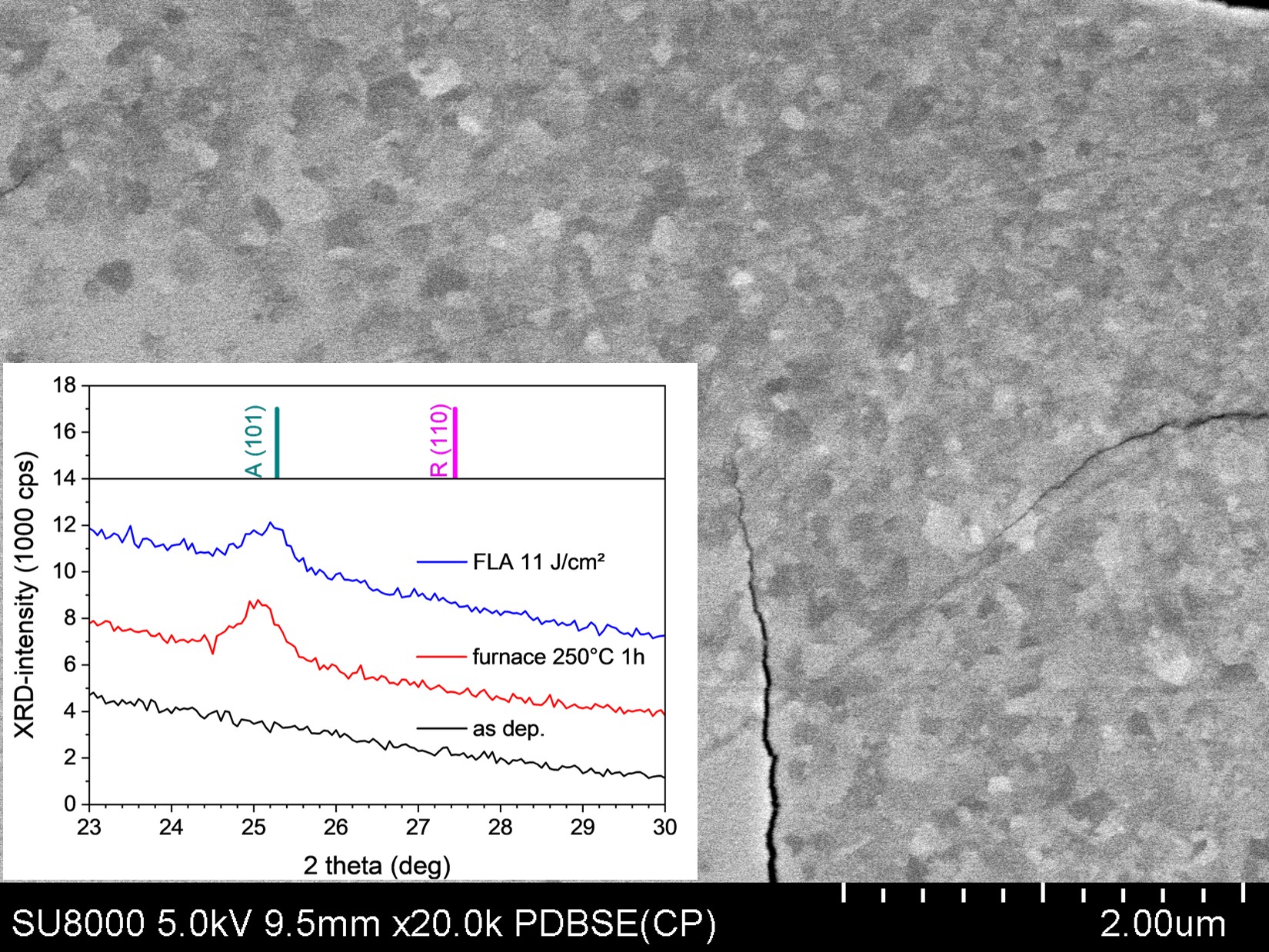

Nanocrystalline structures are required to attach inorganic acidic groups to the titanium oxide layers. The formation of such crystalline structures in titanium oxide layers usually requires process temperatures of at least 250°C, which are problematic for flexible materials such as polymer web. The project is therefore investigating various process approaches that allow crystalline layers to be produced at lower substrate temperatures. At Uppsala University in Sweden, high-power impulse magnetron sputtering (HiPIMS) is one of the methods used to achieve the desired crystallinity of the layers.

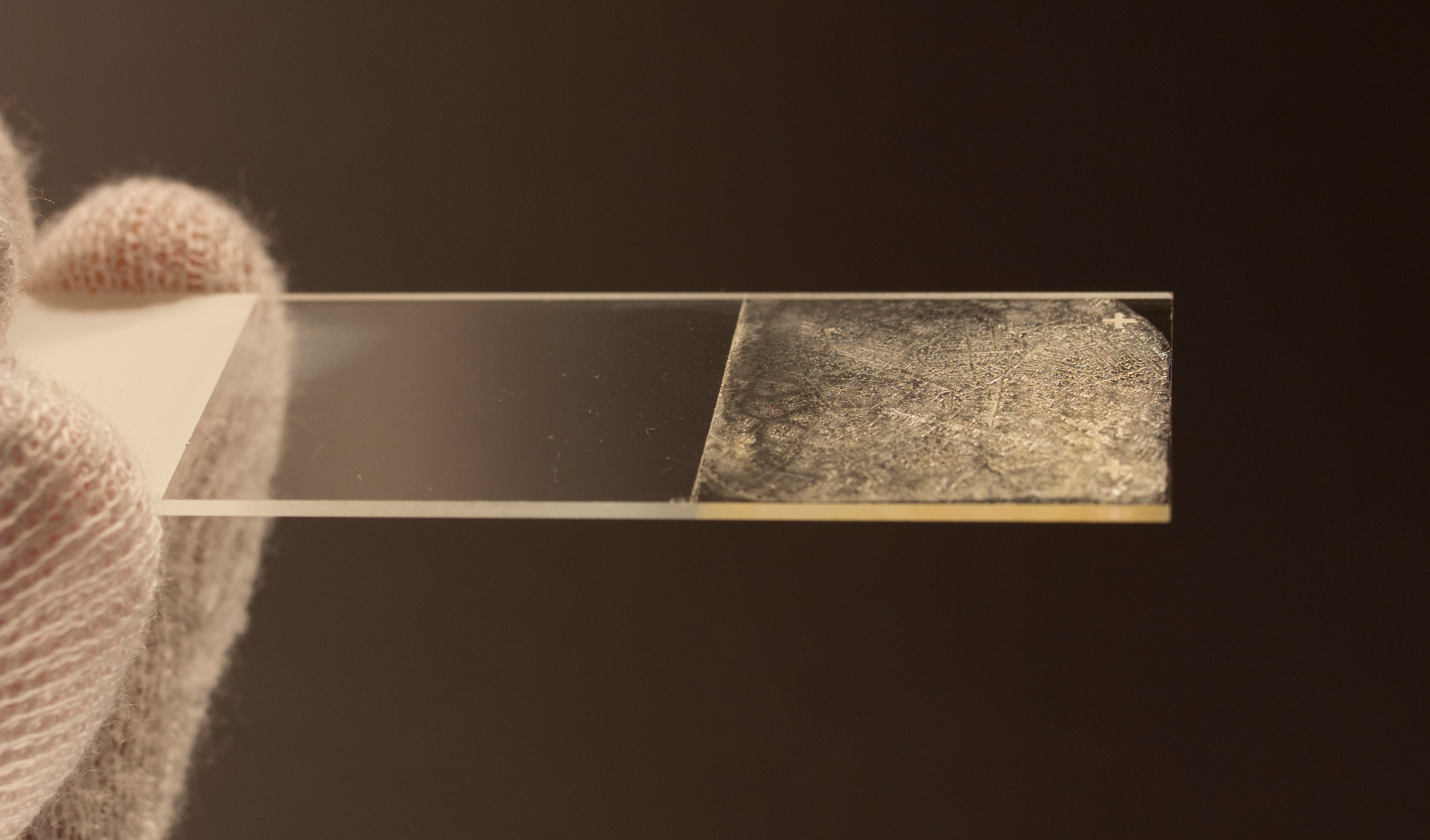

Another approach is being pursued at the Fraunhofer FEP, as project manager Dr. Matthias Fahland explains: “We are using flash lamp annealing (FLA) for producing the crystalline structure of the previously sputtered – still amorphous – TiO2 layers at room temperature. We have already been able to demonstrate the production of crystalline layers using this method on rigid substrates such as glass and on flexible ultra-thin glass as well. With our laboratory and pilot plants, we are able to manufacture and scale up these layers in a reproducible manner. These initial successes will not only enable us to progress in the field of building interior, but can also improve hygiene in public and medical institutions in the future.”

The results were achieved on glass substrates with a size of at least 50 × 50 mm2 in laboratory facilities and in the ILA 900 pilot-scale production facility at Fraunhofer FEP. The latter can process coatings on an industrial scale on rigid glass substrates and has additional equipment to handle flexible thin glass in sheet sizes up to 600 × 1200 mm2 in shade-free processing. The post-treatment process of the FLA is also scalable to this size.

Process transfer to flexible substrates for display films

A central goal of the SanFlex project is to adapt the processes for coating flexible substrates to produce prototype antipathogenic display foils and to demonstrate the effectiveness of the coatings in real hospital environments. Thomas Preußner, technical project manager at the Fraunhofer FEP, describes the current status: “Our first tests of transferring the technology to flexible polymer web already show crystalline structures on those substrates. We are currently working on the stability of the produced layers. To successfully transfer the layer properties to flexible polymer foils, we are using our existing process expertise, while looking at the entire layer production process, starting with the layer deposition by large-area magnetron sputtering, through the crystallization of the layers by inline FLA, as well as the surface bonding process of the inorganic acidic groups.”

If the doubly effective, antipathogenic layers can be successfully produced on polymer substrates, the project partners will be able to use roll-to-roll processes to provide very efficient and economical coating processes, which will support the transfer to industrial production. The Swedish partner ChromoGenics will contribute its expertise in the production of functional polymer foils and is working on roll-to-roll processes within the project.

To ensure that the subsequent introduction of such products into real environments is successful from the beginning, the project partner Fraunhofer ISI will accompany the research work and assess its ecological, economic and social aspects and effects. The Swedish partner Nanoform Science AB is in charge to enable the subsequent commercialization of the results.

The use of such coatings in the construction and building sector, particularly for surfaces, that regularly interact with people, opens new perspectives for hygienic interior solutions that significantly improve health safety. If the scaling-up to cost-effective roll-to-roll production processes are successful, other applications are conceivable in addition to use in the building sector, e. g. in vehicle construction or display applications.

The Fraunhofer FEP scientists will be presenting their initial results during the BAU 2025 trade fair in Munich, Germany, and will be available for discussions from January 13 to 17, 2025 at the joint Fraunhofer booth no. 528 in hall C2.

About the project SanFlex

SanFlex – Antipathogenic touchscreen polymer films

Subproject: Application of flash lamp treatment for the activation of antipathogenic surfaces and socio-economic considerations

Funding authority: The project is funded as part of the M-ERA.NET initiative within the EU Horizon 2020 program, carried out by the Saxon State Ministry of Science and the Arts SMWK

Funding reference number: M-ERA.NET No. 685451, SMWK 100631596/612

Funding period: 1.6.2022 – 31.5.2025

Project partners:

- University of Uppsala, Sweden (project coordinator)

- Fraunhofer Institute for Systems and Innovation Research ISI

- Fraunhofer-Institute for Electron Beam and Plasma Technology FEP

- ChromoGenics AB, Sweden

- NanoForm Science AB, Sweden

Fraunhofer FEP during BAU 2025

January 13 – 17, 2025

Munich Trade Fair Center, Germany

Fraunhofer Joint Booth: Hall C2, booth no. 528

The following topics will be presented at the Fraunhofer FEP during the trade fair:

- Model house with the institute's coating technologies for the construction and building sector, including:

- Low-e coatings

- Thermochromic coatings

- Anti-pathogenic coatings and surfaces

- Anti-reflective coatings for glass applications

- Coatings for ultra-thin, flexible glass

- Barrier coatings for solar applications

- 3D coatings for tube collectors and zeolite heat accumulators

- Structuring processes for design PV applications

- Production of sustainable building materials through biogenic lime synthesis

- Glass modules with anti-reflective coating

- Reconstruction of historical mirrors using mercury-free thin films

Further information: www.fep.fraunhofer.de/bau

Sources

1 C. Suetens et al., “Prevalence of healthcare-associated infections, estimated incidence and composite antimicrobial resistance index in acute care hospitals and long-term care facilities: results from two European point prevalence surveys, 2016 to 2017”, Eurosurveillance, 2018, vol. 23/46.

2 Deutscher Bundestag, https://www.bundestag.de/presse/hib/kurzmeldungen-973282

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam