Thin films for more efficient heat transfer in electrocaloric heat pumps

With the exit from fossil fuels and the achievement of climate targets, alternative technologies are needed for heating and cooling. However, conventional heat pumps and air conditioning systems are noisy, consume a lot of electricity and use refrigerants that are harmful to the climate. This is why scientists around the world are working on electrocaloric heat pumps – they use materials that can change their temperature when an electric field is applied, thereby generating heat or cold. As part of the Fraunhofer lighthouse project ElKaWe, the Fraunhofer Institute for Electron Beam and Plasma Technology FEP has made significant progress in the development of thin films to improve heat transfer in electrocaloric heat pumps. The latest research results will be presented at PSE 2024, September 2 – 5, 2024, in Erfurt, Germany, during the conference and exhibition.

The need for alternative heating and cooling technologies is increasing in view of Germany's ambitious climate targets, which aim to reduce greenhouse gas emissions by 65% by 2030 compared to 1990 levels, and the planned exit from fossil fuels for heating energy. Heat pumps already offer good alternatives for heating in winter and cooling in summer. However, conventional heat pumps and air conditioning systems are noisy, consume a lot of electricity and use refrigerants that are harmful to the climate.

For this reason, scientists around the world are researching the development of electrocaloric heat pumps. Six Fraunhofer Institutes are also working on various key research areas within the ElKaWe lighthouse project. These innovative heat pumps use materials that can change their temperature when an electric field is applied, thereby generating heat or cold. They also do not use harmful refrigerants and are characterized by higher energy efficiency, which leads to a reduction in energy consumption and thus CO2 emissions. The compact design and lower noise levels also make this technology more suitable for use in urban and sensitive environments.

Surface wettability for optimum heat transfer

Heat is transferred in electrocaloric heat pumps by latent heat when the working fluid evaporates or condenses on the electrocaloric materials. Optimum heat transfer requires complete wetting of the surface of the electrocaloric components by the working fluid. Since these surfaces are hydrophobic, i.e. not wettable, the Fraunhofer FEP has developed superhydrophilic metal oxide thin films using magnetron sputtering to address this challenge.

Materials such as titanium dioxide are known for their photo-induced hydrophilicity properties. This means that a wettable surface can be achieved as long as it is regularly activated with UV light. However, regular UV activation is not practical within an electrocaloric heat pump.

The thin films developed at Fraunhofer FEP offer durable hydrophilicity based not only on the intrinsic hydrophilic nature of the materials, but also on their mesoporous microstructure. This microstructure consists of pores with diameters between 2 and 50 nm, which promote capillary effects on the nanometer scale and thus improve the spread of liquids on the surface.

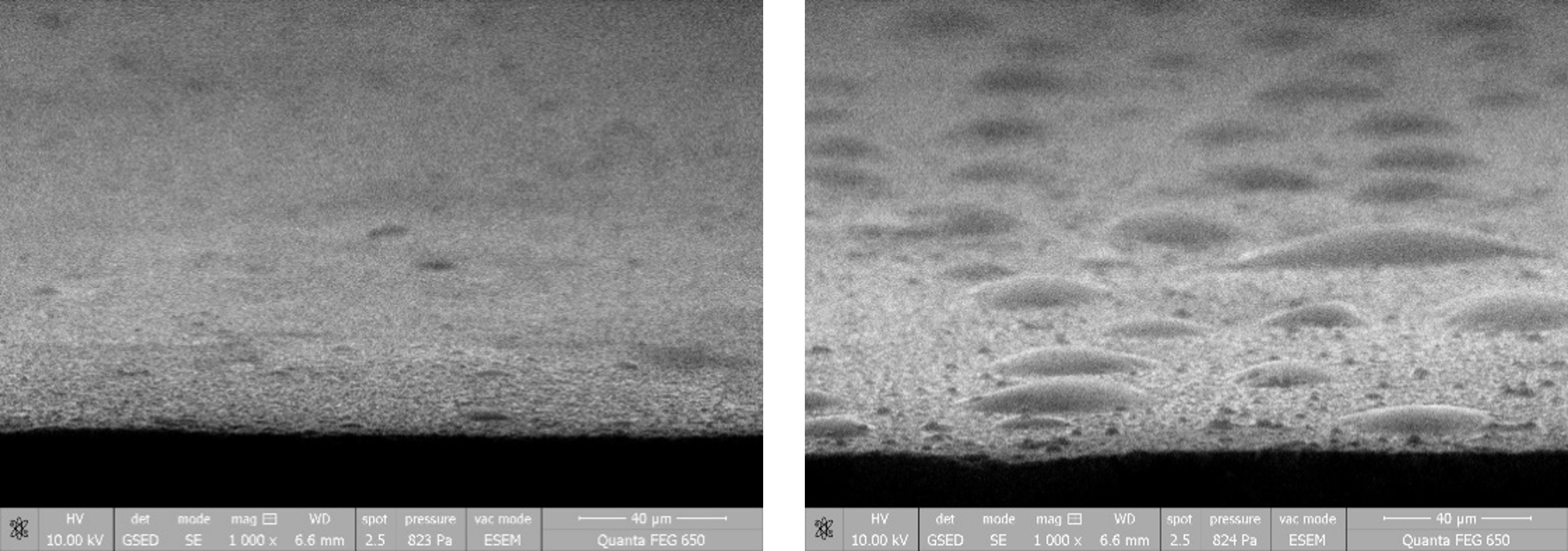

Maria Barrera, PhD student and project team member at Fraunhofer FEP, explains further positive effects: "We have carried out studies on droplet dynamics. The results show that the coated electrocaloric components have a higher droplet nucleation and growth rate than uncoated components. This makes it possible to undergo several cycles of condensation and re-evaporation within one second. Thanks to the mesoporous coatings, almost the entire surface remains active during the condensation processes, which significantly improves the heat transfer performance."

Superhydrophilicity through metal oxide thin films using magnetron sputtering

Investigations into droplet condensation have shown that the new coatings can improve the heat transfer rate by up to two orders of magnitude by accelerating droplet growth. Condensation and evaporation processes take place significantly faster on superhydrophilic coated surfaces than on the uncoated ones.

For decades, the Fraunhofer FEP has been an expert in the development of thin, functional coatings and processes for their deposition from laboratory to pilot scale. One of the institute's core competencies lies in the realization of ultra-thin layers using magnetron sputtering processes. The hydrophilic metal oxide layers were produced at laboratory scale in the institute's own batch system for coating 3D substrates, UNIVERSA.

The achieved permanent superhydrophilicity of the layers makes these coatings particularly suitable for use in solid-state cooling devices such as electrocaloric heat pumps. In addition, these thin films can be used in applications where rapid droplet nucleation or complete wetting of the surface by a liquid is crucial.

"The development of the electrocaloric heat pump has the potential to become a game changer for sustainable heat pump technology," continues Maria Barrera. The researchers are currently working at laboratory scale and the purpose is to further develop the technology so that it can be ready for the market in 5 – 7 years. One focus in the ongoing development of this promising technology is on polymer-based electrocaloric heat pumps of the future. The researchers are open to follow-up projects and will present the current results at the PSE 2024 conference in Erfurt, Germany, from September 2 – 5, 2024.

Fraunhofer FEP zur PSE – 19th International Conference on Plasma Surface Engineering 2024

Exhibition

September 3 – 4, 2024

INPLAS booth no. 24-26

Congress Center Erfurt

https://pse-conferences.net

Conference

Monday, September 2, 2024

Session S03: Optical, electronic and magnetic coatings I

Christian-Reichard Saal

2:45 – 3:00 pm

OR0302: Transparent high permeation barrier coatings for flexible large-area opto-electronics (#467)

P. Schlenz et. al, Fraunhofer FEP

4:45 – 5:00 pm

OR0308: Sputter deposited Aluminumoxynitride films for applications as electricals isolating, thermally conductive films (#379)

H. Bartzsch et. al, Fraunhofer FEP

Tuesday, September 3, 2024

Session S08: Environmental Applications

Car Zeiss Saal links

3:00 – 3:15 pm

OR0801: Magnetron-sputtered thin films enabling heat transfer enhancement in electrocaloric heat pumps (#303)

M. Barrera Marin et. al, Fraunhofer FEP

4:45 – 5:00 pm

OR0806: High-rate deposition of Al-Mo multilayers and their potential for corrosion protection (#583)

F. Fietzke et. al, Fraunhofer FEP

Session S09: Physical vapour deposition II

Carl Zeiss Saal rechts

5:00 – 5:35 pm

OR0907: Large area antipathogenic surfaces based on crystalline TiO2 thin films processed by PVD in combination with Inline Flash Lamp Annealing (#461)

T. Preußner et. al, Fraunhofer FEP

Wednesday, September 4, 2024

Session S12: Biomedical and agriculture applications

Carl Zeiss Saal left

12:45 – 1:00 pm

OR1208: Opportunities and challenges for the use of plasma-activated water as a germicidal agent (#225)

L. Steinhäußer, Fraunhofer FEP

Session S13: Physical vapour deposition III

Carl Zeiss Saal right

10:45 – 11:00 am

OR1302: Influence of oxygen incorporation on film properties of magnetron sputtered AlScN thin films (#376)

S. Barth et. al, Fraunhofer FEP

About Fraunhofer lighthouse project "Electrocaloric heat pumps (ElKaWe)

The Fraunhofer lighthouse project ElKaWe started on October 1, 2019 and will run for four years. The project is funded by the Fraunhofer-Gesellschaft with a total of 8 million euros.

The following Fraunhofer Institutes are involved in the project:

- Fraunhofer Institute for Physical Measurement Techniques IPM (project coordination)

- Fraunhofer Institute for Ceramic Technologies and Systems IKTS

- Fraunhofer Institute for Applied Solid State Physics IAF

- Fraunhofer Institute for Applied Polymer Research IAP

- Fraunhofer Institute for Structural Durability and System Reliability LBF

- Fraunhofer Institute for Electron Beam and Plasma Technology FEP

Further information: www.elkawe.org

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam