Innovative pilot line for the vacuum coating and thermal post-treatment of flexible ultra-thin glass

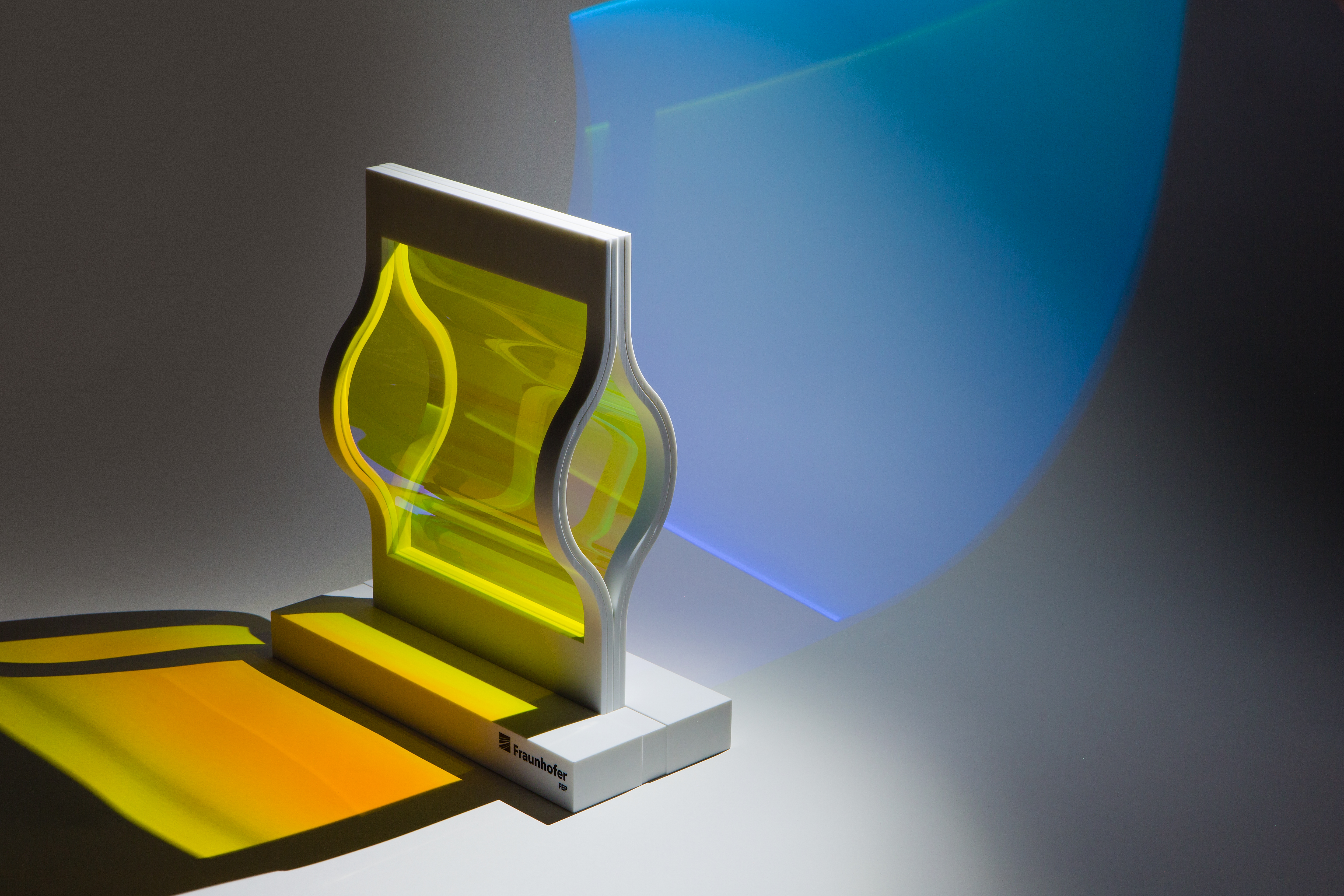

Flexible ultra-thin glass is an innovative material that combines the chemical resistance and scratch resistance of glass with the flexibility and weight reduction of plastics, primarily due to its low thickness of ≤ 100 µm. Processing ultra-thin glass requires special handling to prevent breakage during production, which has been a major barrier to its introduction into new applications. Within the Glass4Flex and CUSTOM projects, funded by the Federal Ministry of Education and Research (BMBF) and the Federal Ministry of Economics and Climate Protection (BMWK), project partners at the Fraunhofer Institute for Electron Beam and Plasma Technology FEP developed a unique process chain for the in-line coating of ultra-thin glass. They also evaluated suitable characterization methods for the surface and edge strength of the thin glass to further optimize the material properties through flash lamp tempering. A demonstrator of flexible thin glass with an optical interference layer system will be showcased at glasstec 2024 in Düsseldorf, Germany, from October 22 – 25, in the glass technology live area in Hall 11, Stand No. F27.

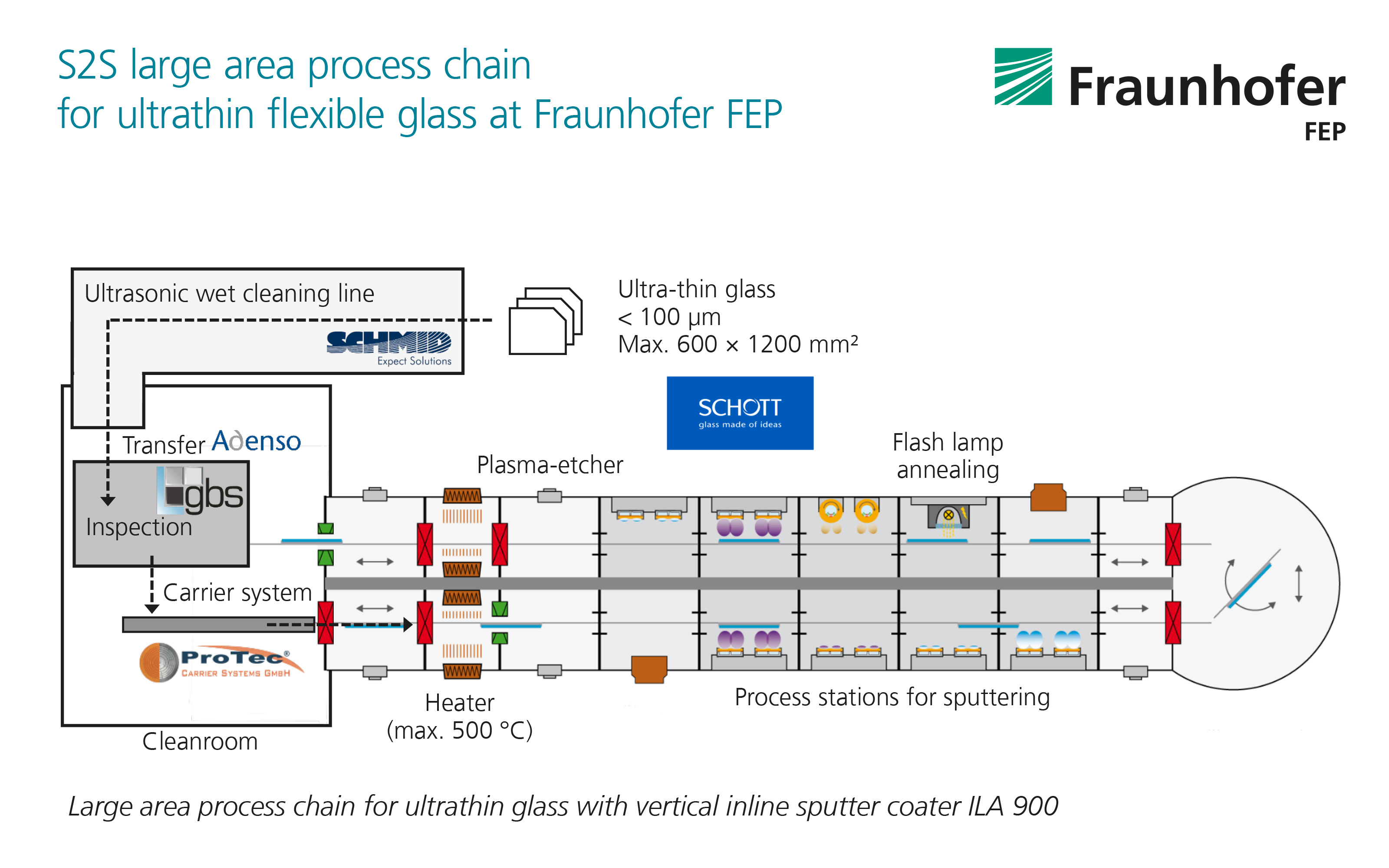

Ultra-thin glass, with a thickness of 100 micrometers or less, offers great potential for modern high-tech applications. Despite its superior properties, such as a smooth surface, high transparency, and excellent barrier properties compared to polymer films, the material has not yet established itself in the mass market beyond foldable displays. A key obstacle is its tendency to fracture, typical of glass, which necessitates adjustments along the entire process chain. This process chain is now available at the Fraunhofer FEP in Dresden as a development and technology platform for feasibility studies up to pilot scale. It addresses innovative issues ranging from cleaning to scaled in-line sputter coating, and from handling and transfer to thermal post-treatment of thin glass.

To demonstrate the functionality of the process chain, two coating systems were produced at the Fraunhofer FEP on large-format thin glass: one on 100 µm thick glass with an area of 400 × 400 mm² and another on 700 µm thick glass with an area of 600 × 1200 mm². An anti-reflective coating system consisting of nine layers of zirconium oxide and silicon oxide (ZrO2 / SiO2) and a transparent conductive indium tin oxide (ITO) layer were examples of electrode applications. The suitable process parameters of the in-line sputtering processes achieve homogeneous layer properties across the entire surface without edge shading due to the innovative integration of a flat carrier for the thin glass using moving electrostatic chuck systems from Glass4Flex partner ProTec Carrier Systems GmbH. For both application examples, minimizing mechanical layer stress during the sputtering process is essential. For the ITO coating realized at room temperature, it is also necessary to enhance the conductivity and transparency of the layers through thermal post-treatment. Flash Lamp Annealing (FLA) using a Xenon flash lamp with energy densities up to 50 J/cm² and pulse durations in the millisecond range is an energy and cost-efficient method compared to conventional furnace annealing.

Strength testing of ultra-thin glass: the key to success

A critical factor in all these processes is the strength of the glass, which is affected by each step, from cutting to plasma pre-treatment to improve adhesion, coating, or thermal post-treatment. Strength testing of flexible thin glass is therefore of particular importance. Currently, there are no standard procedures for testing thin glass. Standardized methods from the fields of architectural glass or optical applications cannot be used or can only be used to a very limited extent, due to the inherent flexibility of thin glass.

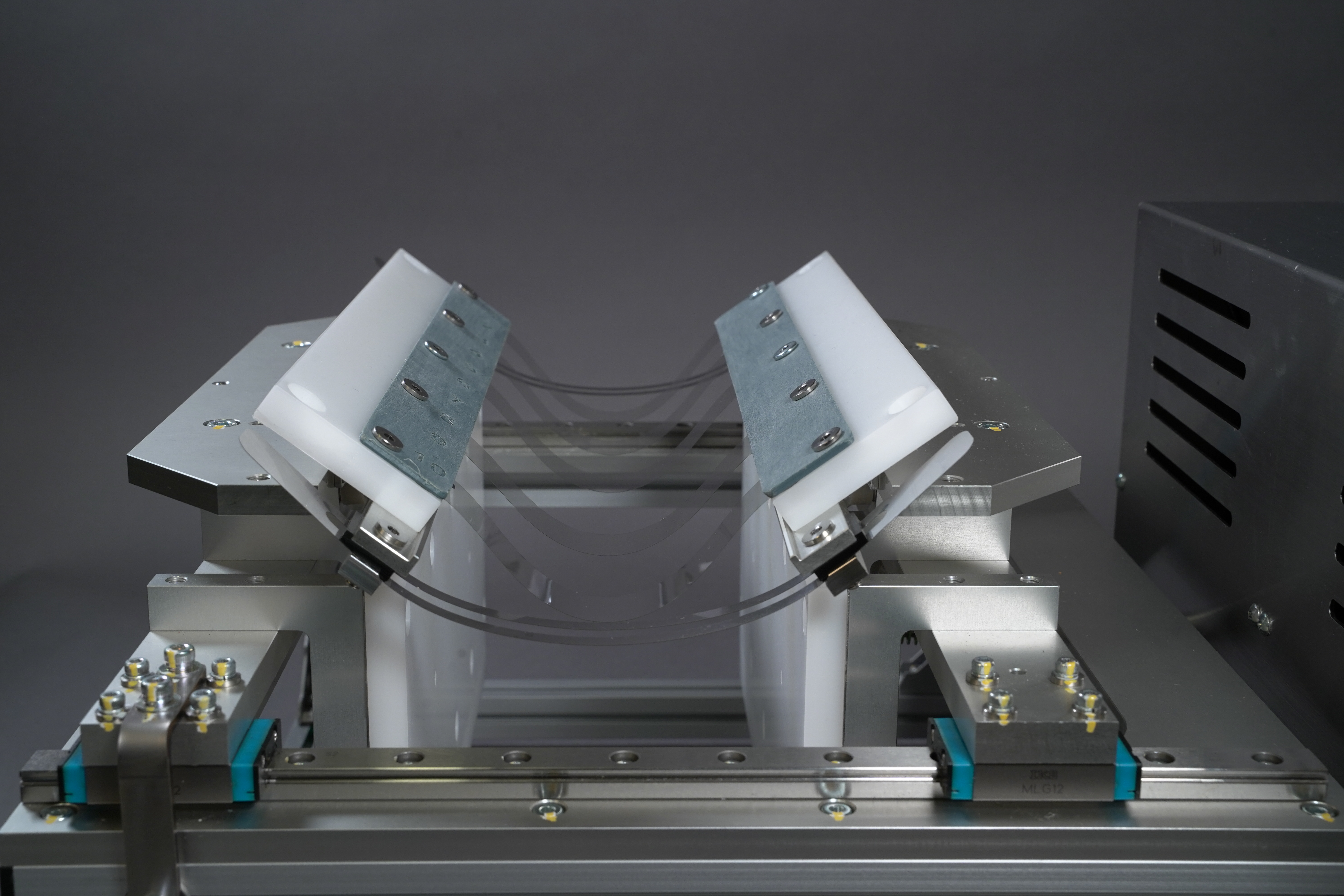

During the project, the Fraunhofer FEP adapted and further developed several mechanical test methods to characterize the surface or edge strength and fatigue properties of thin glass. Among other innovations, a thin glass adapted YUASA flexure tester from Bayflex Solutions' CUSTOM project portfolio was utilized.

Applications and future developments

Dr. Kerstin Täschner, project manager at the Fraunhofer FEP, outlines the researchers' next steps: "Interesting approaches for future applications of both the innovative thin glass material and plasma coating and post-treatment processes aim to ensure high edge and surface strength throughout all process steps. Our research also focuses on production processes that will enhance strength in the future. This can be achieved through appropriate process control in coating and FLA post-treatment, as well as suitable FLA treatment approaches to increase the surface strength of the glass itself. We have already achieved a very promising effect for 3 mm thick natron-lime glass using flash lamp tempering."

Future research projects will investigate the effect of tempering on different types of glass and thinner glass, as established tempering processes such as chemical ion exchange or thermal tempering do not achieve the desired effect, especially with thinner glass.

The Fraunhofer FEP is actively working on further developing these technologies. This expertise and the thin glass process chain are available to industrial partners as a technology and development platform, ranging from initial feasibility studies to large-scale development or pilot-scale sampling.

Fraunhofer FEP at glasstec 2024

Exhibit of a coated ultra-thin glass

Special area glass technology live

Hall 11, booth no. F27

Presentation

Sputtered functional coatings on ultra-thin flexible glass in sheet-to-sheet pilot scale processing

Dr. Jörg Neidhardt, Fraunhofer FEP

Session: glass melting pot

October 22, 2024, 4:40 - 4:50 p.m.

Stage at glass technology live / Hall 11 B28

About the projects

Glass4Flex – New process technologies pave the way for the use of flexible glass in optical systems

Funding body: Federal Ministry of Education and Research

Funding reference: 13N14615

Duration: 2019 – 2024

www.photonikforschung.de/projekte/optikkomponenten/projekt/glass4flex.html

Project partners:

- SCHOTT AG

- SCHMID Group

- Gesellschaft für Bild- und Signalverarbeitung (GBS) mbH

- Adenso GmbH

- ProTec® Carrier Systems GmbH

CUSTOM – Investigation of the material behavior of ultra-thin flexible glass in a layered composite

The project is being carried out by the Fraunhofer FEP in collaboration with the Fraunhofer IMWS.

Funding body: Federal Ministry for Economic Affairs and Energy

Funding reference: 21708 BR

Duration: 01.03.2021 - 28.02.2023

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam